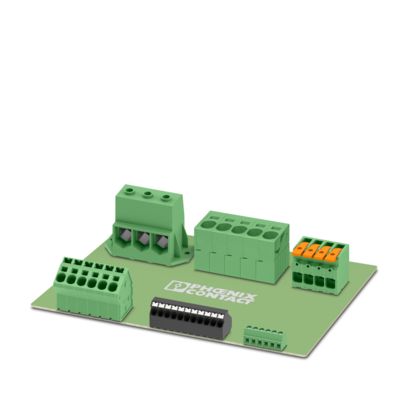

Preliminary testing for connectors and electronics housings Quality right from the development process: State-of-the-art simulation tools are used in the Phoenix Contact laboratories to optimize the development process and quality right from the start. Preliminary tests provide the optimal conditions for testing the long-term stability of the products right from the start of the development phase.

Test concept meeting

Advanced quality planning

Advanced quality planning is an established approach to preventing potential errors and continuously improving products and processes. Following ISO 9001, TS 16949, and VDA, product and process features to be developed are harmonized, test concepts worked out, test methods and test classification are taken into consideration, and product specifications defined in the form of necessary production documents. The knowledge gained is continuously applied in the development of new products.

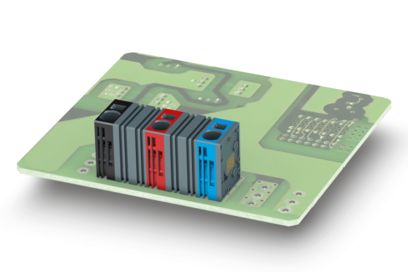

Failure mode analysis

Failure mode analysis

Product and process-related failure mode and effects analyses are performed in interdisciplinary project teams. The goal is to identify, trace, limit, and eliminate potential weaknesses and risks. The measures determined in this analysis are documented and monitored. They are used as the basis for further activities in advanced quality planning to optimize designs as well as the existing or planned production facilities.

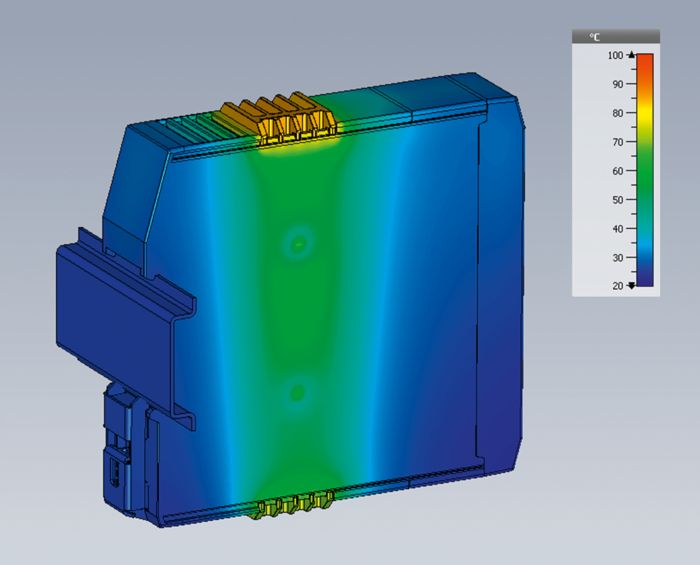

Heat simulation of an ICS series electronics housing

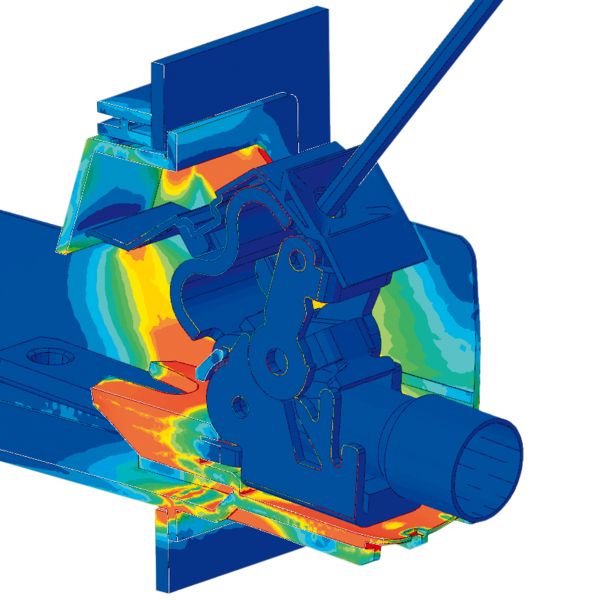

Computer-aided simulation

The FEM calculation (Finite Element Method) allows engineers and designers to evaluate whether the materials and geometries selected for a product meet the high demands of industrial use. As early as the initial stages of development, products can be optimized. The FEM analysis allows both operation by the users to be simulated and the desired long-term behavior to be verified.

Development team discussing test results

Product and process approval

The structured product and process approval (PPA process) verifies whether the customer requirements agreed on in the specifications are met as well as the corresponding regulations and standards. The approval issued during the procedure covers the evaluation of the processes and products using relevant documents, drawings, and samples. This ensures that the conditions for serial delivery to the customer are assured.