Environmental and durability tests for connectors and electronics housings High quality through maximum resilience under extreme external influences in test batch D: Our products are subjected to extreme climatic conditions such as temperature shocks in order to test their durability. IP protection classes and vibration resistance are also verified. The aim of the tests is to achieve high quality, durability, and reliability under the harshest conditions.

As the fourth milestone prior to series release, test batch D includes the following laboratory tests:

- Degree of protection tests (IP classification) in accordance with DIN 40050-9-60529

- Vibration tests: Sine waves, resonance search, mechanical shock, broadband noise (IEC 60068-2-6)

- Corrosion tests: Salt-spray test, Kesternich test (SO2), condensation climate, flowing gas mix (IEC 6988)

- Climate tests: Heat, cold, humidity, temperature shock

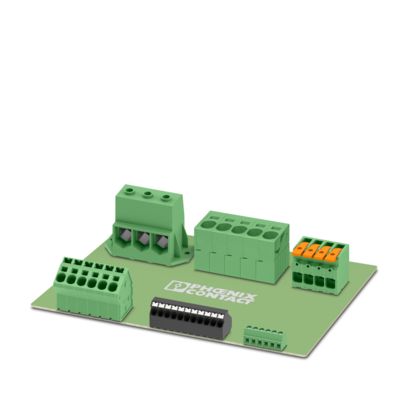

Dust test for an electronics housing

Degree of protection test in accordance with DIN 40050‑9/60529

The IP classes describe the protection of a housing from contact with dangerous parts as well as the penetration of foreign bodies or water. Phoenix Contact has the necessary equipment for reproducibly testing the test objects for contact, water and, dust protection according to currently valid standards.

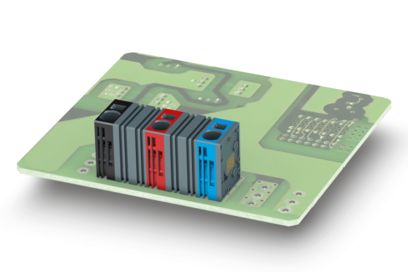

Corrosion test in a testing laboratory

Corrosion test in accordance with IEC 6988

High-quality, gas-tight connections demonstrate a corrosion-free and constant low-ohm contact area even when exposed to the effects of aggressive media. During the Kesternich test, the test object is exposed to a sulphur-oxidic atmosphere at an ambient temperature of +40°C. After a subsequent drying period, a visual inspection is performed and the transition resistance is measured to assess the influence of the corrosive environment on the contact point.

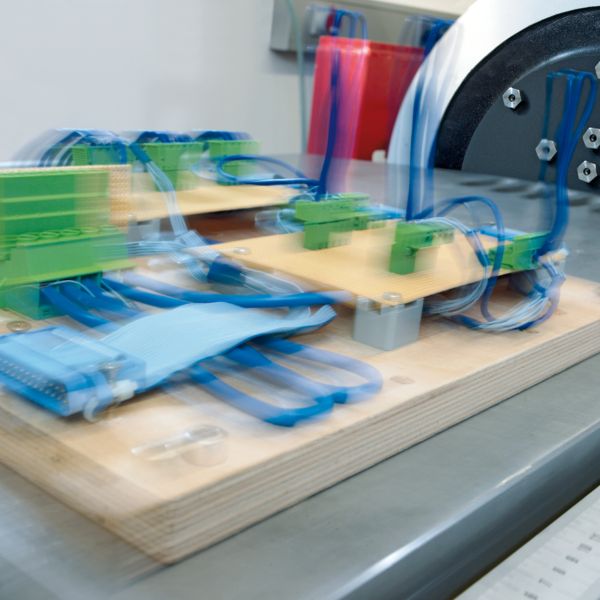

Vibration test on a SKEDD direct connector

Vibration test in accordance with IEC 60068‑2‑6

This test demonstrates the vibration resistance of an electrical connection. Harmonic, sinusoidal vibrations are applied to the test object to simulate rotating, pulsating, or oscillating forces. Along all three axes, frequencies in the 10 to 2,000 Hz range, for example, are successively applied at a rate of one octave per minute. The test object may in no way sustain damage that might impair further use.

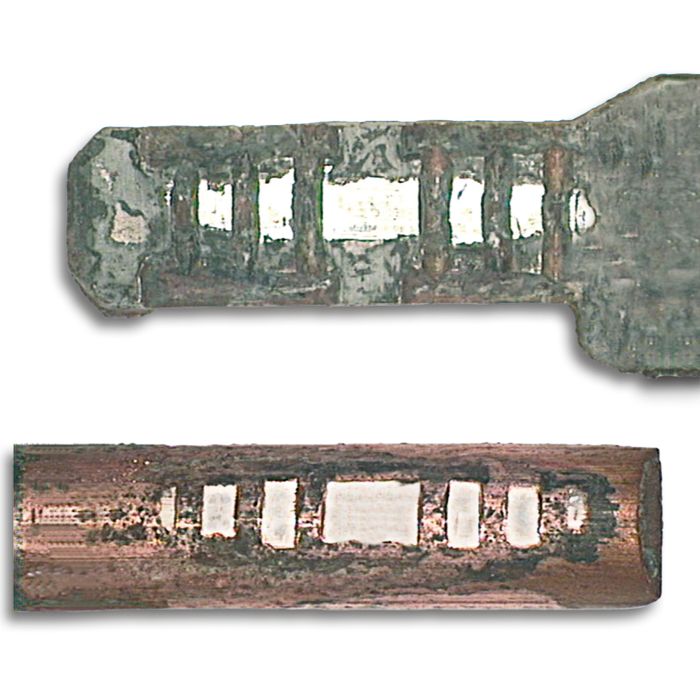

Temperature shock test on a connector in the laboratory

Temperature shock test in accordance with IEC 60512‑11‑4, test 11d

In industrial applications, process-related temperature changes may occur. To simulate such conditions, electrical connections are subjected to extreme temperature changes in the climatic chamber. In a two-chamber procedure, the test objects are moved between their lower and upper limit temperature within just a few seconds and usually remain there for 45 minutes. This must not result in damage that might impair further use.