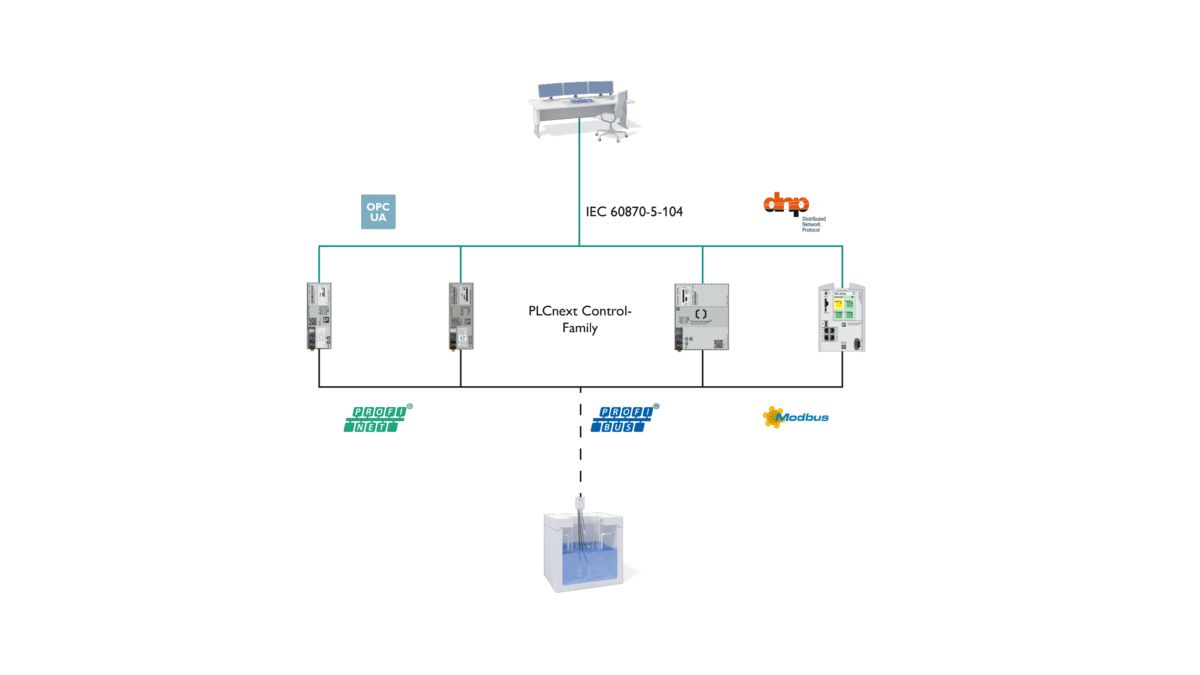

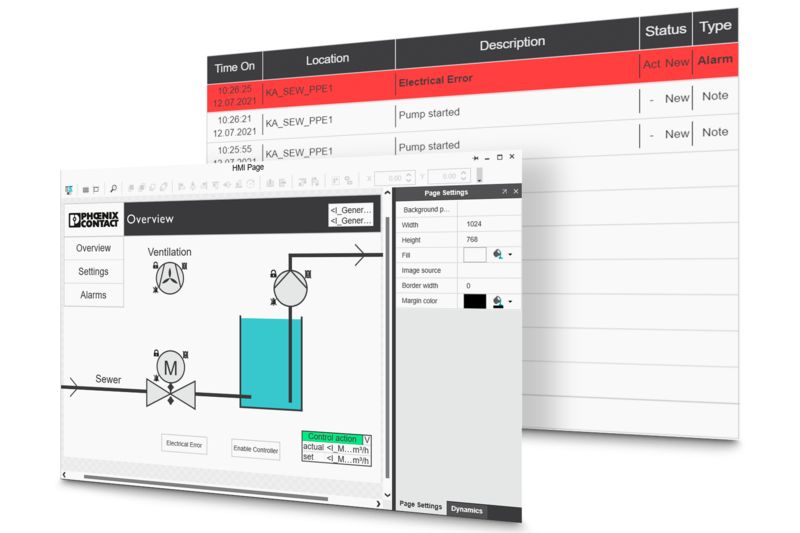

The first surface water processing stage takes place in a rotary drum system. The PLCnext Control family of modular control technology facilitates reliable control of filtration based on the measured values acquired through various standard interfaces.