Sustainability without cracks or folds In automotive engineering, surface quality is the crowning discipline – with its sensor technology and digitalization, the retrofit system achieves greater process transparency, even in older press lines.

Brief summary

It is always good to know what is going on. This statement becomes increasingly important in metal processing, in particular when countless process parameters influence the results when manufacturing thin materials – e.g., when “forming” sheet metal in the automotive industry.

Together with Phoenix Contact, iLARIZ has succeeded in creating a digital system that creates greater transparency in the deep-drawing process for sheet metal parts. This autonomous system can be retrofitted in deep drawing tools. This paves the way for the production of sophisticated lightweight construction materials with high quality and low reject levels in all their press lines – even the older lines.

Dr. Apostolos Papaioanu (iLARIZ) on assignment: first test of the application in the press shop

More knowledge about the processes in pressing tools

Preferably light, preferably thin, preferably solid. The demands placed on lightweight materials are quick to list. However, the pursuit of increased lightness also has its limits – and these are reached at the latest when components no longer achieve the required stability or when high-strength materials are difficult to form. Sheet metal in, press operated, component out: The details of everything that happens during the deep-drawing process are almost impossible to access by those responsible for the process in everyday practice. As soon as the press closes, the process – literally bending and crushing – is subject to its own laws.

The particular challenge here is that changing parameters such as temperature, friction, and above all, fluctuations in properties in the material, as well as wear, all have an effect. If things go badly, the workpieces leave the deep-drawing mold with cracks and folds – and therefore become expensive scrap. What can also become a real problem is the lack of dimensional accuracy due to process deviations in sheet metal processing. Tolerances in the tenth of a millimeter range can cause massive disturbances in the body shop – with correspondingly high costs and negative effects on the OEE, the overall equipment effectiveness.

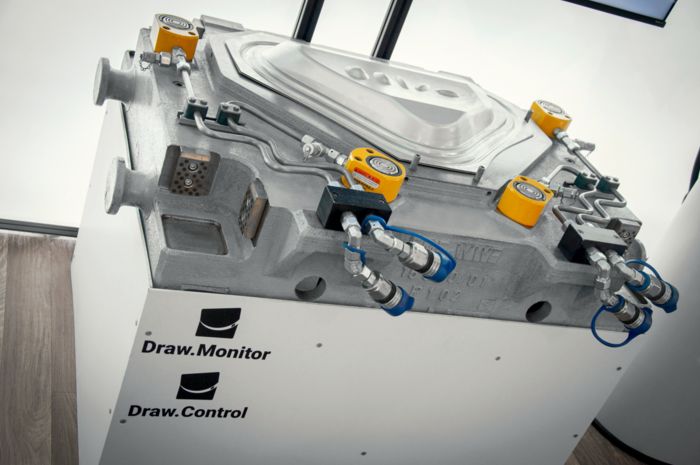

The iLARIZ solution can be retrofitted in existing press tools. Photo: iLARIZ

Retrofittable solution reduces rejects

This is exactly where iLARIZ comes in. The Stuttgart-based company is equipping the tools in the press shops with autonomous power and position sensors. Both of these parameters are essential for evaluating a press process and, in the best case being able to control it using hydraulic valves. This approach becomes visible in the form of gradient curves or movement profiles. iLARIZ took the conscious decision to equip individual tools and not the entire press line with piezo sensors. “There are considerably more tools than presses in production, and the tools are rarely permanently connected to a production site. It is not uncommon that tools are moved between locations”, says Stefanie Sobola, Software Developer and Marketing Manager at iLARIZ. The digital sensor system that is linked to one tool therefore works autonomously and independently of the permanent OT and IT infrastructure on site.

To this end, iLARIZ connects the piezo sensors via PROFINET directly to the EPC 1522 edge computer within the PLCnext Technology ecosystem. The compact device is designed primarily for protocol conversion, data acquisition, and edge computing. For data processing and visualization, the Stuttgart-based company relies on Cumulocity IoT and thin-edge.io, which is available via the PLCnext Store. Because the data acquisition and analysis is edge- and cloud-based, the system does not require complex integration into existing IT/OT infrastructures. This means that it is much easier to integrate, in particular with regard to interfaces and, above all, security. The same applies to the use of the sensors. “We make the details understandable and traceable. As part of our product development, we therefore also want to integrate more AI and machine learning systems – and thus offer our customers the opportunity to maximize the robustness of their production lines and make their processes more transparent. In addition, we are striving to extend our market presence internationally”, explains Christian Held, who founded the company along with Dr. Apostolos Papaioanu.

A valuable contribution to sustainability and resource protection

When setting up its two products, Draw.Control (automatic process control) and Draw.Monitor (visualization and analysis), iLARIZ installs sensors at several points on a tool as part of its patented process. With this approach, the young company is able to collect measured data in different areas of a tool – in order to then gain an overall picture for each individual production cycle. Ultimately, the system provides integral process variables that can be compared with a digital fingerprint for each individual component.

Draw.Control goes one step further and controls the hydraulic actuators in accordance with the determined data, replacing conventional manual setting aids. A part of iLARIZ’s core expertise is knowing where, in both areas of application, which sensors are best placed and how many are needed per tool. What the people in Stuttgart lacked in order to create marketable product was an automation partner who could translate the idea into control technology and, ideally, deliver it fully configured in a ready-to-connect control box. In the revised system, which was designed in a close project partnership between Phoenix Contact and iLARIZ, the already-mentioned PLCnext Control will be the heart of the system in the future.

Dr. Apostolos Papaioanu, iLARIZ (left) and Thanh An Pham, Phoenix Contact (right) sealing their partnership at BlechExpo 2023

Partnership for the factory of tomorrow

Another special feature of the system developed by iLARIZ – decided upon at the very beginning – is that the retrofittable tool control system has been set up using components that are already established in the automotive industry. “The hardware must be known in the press shop”, emphasizes Christian Held. Anyone who does not conform with factory specifications generally has little chance of gaining a foothold in this industry with a new product, whether it be a controller or hydraulic valve. “And therefore, we were looking for a partner who could work with us to design the control technology and bring the whole thing to the cloud”. Christian Held summarizes. “We view Phoenix Contact to be the empowering force that provides us with ideal support so that we can focus on our core fields of expertise. This expertise is clearly in process knowledge, in forming metal precisely and with repeat accuracy”, explains Dr. Apostolos Papaioanu continues.

To produce more precisely while saving time, generating less waste, and making the process more reliable in the long term: at the end of the day, each resource saved has a fully positive effect on climate protection and profitability. Together with the “Digital Factory now!” approach from Phoenix Contact, Draw.Control and Draw.Monitor provide the basis for being able to intervene in processes at an early stage – in order to avoid rejects and, ultimately, to reduce carbon emissions. “Only a small part of the scrap makes its way back to the automotive industry as a new material due to quality requirements – so it does not find its way back to the original application”, explains Christian Held. Each unit reduction in waste means less effort and energy is needed to be put into recycling – thereby tangibly increasing sustainability in the value chain.

Summary

Increased sustainability, greater cost-effectiveness: a look at sheet metal processing shows how digitalization and the targeted use of sensors and actuators in deep drawing tools can lead to greater process knowledge. The use of an autonomous system with cloud connection means that this modernization is free of restrictions in terms of CE, security, and interfaces. “Our collaboration with Phoenix Contact was and continues to be extremely productive, inspiring, and on an equal footing. Their expertise and support is very valuable for us and, especially with regard to the requirements placed on our controller, they have helped us to realize our innovative approaches even more efficiently”, says Dr. Apostolos Papaioanu about the cooperation.

At Phoenix Contact, the integration of sensors is considered to be an important switchover to digitalization. The data generated, and the associated density of information, enables the various sectors to be coupled as part of an All Electric Society – with the aim of increasing resource efficiency.

Connect with our experts

More posts

Sector coupling needs consistent communication

An interview with Martin Müller of Phoenix Contact on the lack of standards and looking beyond the horizon of the fieldbus world.

Coupling of factory and building

The Emalytics Automation building management system harmonizes data formats and intelligently networks sectors.

5G campus networks

Industrial application examples for wireless broadband communication.