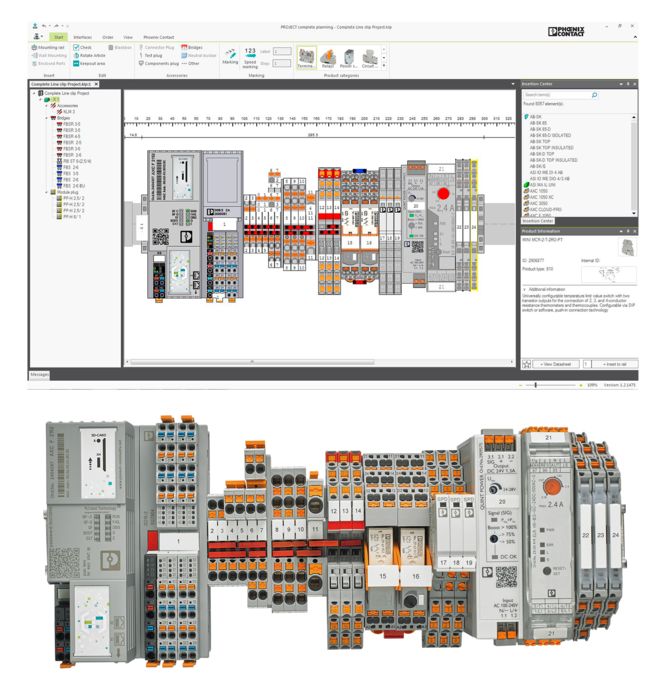

From planning through to the finished control cabinet The PROJECT complete planning and marking software guides you through all the phases of terminal strip configuration. The software provides you with individual and convenient process support – from electrical planning through to delivery of your finished product. Find out more in the “PROJECT complete” brochure.

Efficient planning with PROJECT complete

Efficient planning with PROJECT complete

Intuitive configuration, intelligent functions, and a customizable user interface: The PROJECT complete planning and marking software is the innovative solution for the easy planning of your terminal strips and the straightforward creation of the corresponding markings.

From the transfer of data from electrical planning to delivery of your finished product, the software features individual and convenient process support.

Items with digital descriptions provide the basis for optimized processes

All items have digital descriptions

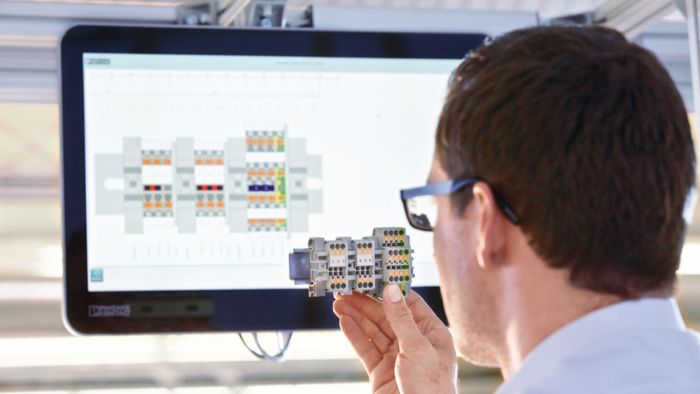

All items have digital descriptions and together with standardized data and system interfaces provide the basis for optimized processes in control cabinet manufacturing.

Uniform digital item descriptions support engineering, installation, production, and maintenance. This means that all operating states are known at all times; their visualization simplifies planning, analysis, and operation. Furthermore, digital item data is required in order to produce individual products at marketable prices. All COMPLETE line items come with digital descriptions and have standardized product data, such as ETIM, eCl@ss, or UNSPSC data. All the digital item data can be found directly on the product.

Configure our products to suit your requirements

Always the right product selection

Our configurators support you in finding the right product or the right solution for your application according to your specific requirements.

With straightforward filter menus, 2D and 3D product images, and the intuitive user interface, you can configure your individual solutions in just a few steps – without any errors.

- Convenient configuration: Just a few entries to create your desired solution

- Intuitive operation: Simply move the components to the desired position using drag and drop

- User-friendly visualization: Real-time 3D representation of your configuration

- Easy planning: Simply download the combined 2D and 3D data and import it into your CAD program

Network on a global scale with PROFICLOUD

Professional cloud solutions

With digitalization on the rise, there is a need to integrate data analysis into company processes.

Proficloud from Phoenix Contact offers comprehensive cloud solutions that are tailored to your needs. Network your production and development operations worldwide beyond enterprise boundaries. With Proficloud, you can capture your machine and system data from anywhere in the world and combine large volumes of data from different sources. Using modern data analysis as a foundation, you can make informed decisions, produce forecasts, and improve your operations process control.